Across the vast expanse of industrial operations, where bulk material management is paramount, Little P.Eng. Engineering has etched a significant mark. The firm’s reputation in structural and mechanical design extends beyond just equipment, touching several critical aspects of material management. This article will delve into how Little P.Eng. Engineering is transforming four pivotal sectors: Material Handling Facilities & Building, Bulk Material Transport, Bulk Material Treatment, and Bulk Material Transfer.

Little P.Eng. Engineering is an American / Canadian company that provides economical bulk material handling engineering services that are designed to meet the specific needs of our customers. We have a long history of partnering with supervisors, engineers, planners, and vendors, across a wide variety of industries to provide bulk material handling engineering solutions and systems that improve safety and productivity. Whether you need help designing, installing or maintaining any aspect of your bulk material system, we have the skills and experience to meet your needs.

Our bulk material handling engineering specialists can re-engineer and upgrade existing systems while providing customer solutions and processes. We work with customers through every part of the engineering process to create a one-stop destination for all their needs.

We also work to provide superior customer service that extends well beyond the initial installation or execution of a solution. Our customers can contact us and receive immediate assistance whenever needed for continued support that keeps businesses up and running without having to worry about delays or downtime.

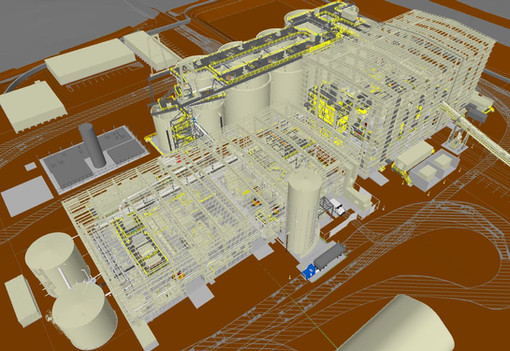

1. Material Handling Facilities & Building

Material handling facilities are the heartbeats of many industries. From mining to agriculture and manufacturing, they facilitate the smooth and efficient movement of bulk materials.

- Understanding Infrastructure Needs: Little P.Eng. Engineering begins its design process with a comprehensive study of the client’s requirements. The aim is to understand the volume of material to be handled, the rate of throughput, and the kind of materials involved.

- Structural Integrity: Buildings designed for material handling need robust foundations. Little P.Eng. ensures that every facility they design can withstand the tremendous loads and stresses associated with bulk material handling.

- Optimized Workflow Design: Beyond just structural integrity, Little P.Eng. focuses on creating a streamlined workflow within these buildings. Through the strategic placement of equipment, chutes, conveyors, and storage areas, they ensure that materials move seamlessly, minimizing disruptions and maximizing efficiency.

- Innovation at the Forefront: Little P.Eng. is known for incorporating innovative solutions like automated sorting systems, advanced ventilation systems, and sustainable energy solutions, making these facilities both state-of-the-art and environmentally responsible.

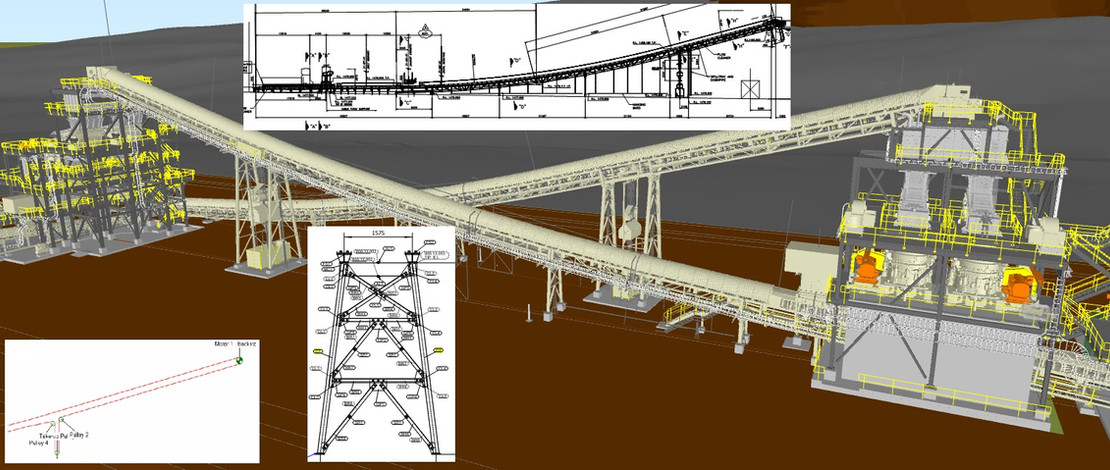

2. Bulk Material Transport

Once materials are sourced and sorted, they need to be transported. Little P.Eng. Engineering has a vast portfolio of solutions tailored to this very requirement.

- Vehicle Design: Depending on the type of material, the firm designs transport vehicles, whether trucks, railcars, or even conveyor systems. Their designs emphasize both capacity and safety, ensuring that large volumes can be transported without risks.

- Infrastructure Design: Little P.Eng. also specializes in designing transport-related infrastructure. This includes everything from loading and unloading docks to advanced conveyor belt systems and even pneumatic transport solutions.

- Addressing Challenges: Transporting bulk material is fraught with challenges like spillage, degradation, and contamination. Little P.Eng.’s designs account for these challenges, providing solutions such as sealed transport containers and dust suppression systems.

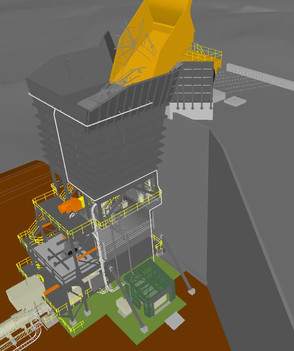

3. Bulk Material Treatment

Treatment of bulk materials, whether it’s refining, purification, or simply grading, is a complex process. Little P.Eng.’s role in this domain is critical.

- Treatment Facility Design: Little P.Eng. engineers facilities where bulk materials undergo various treatment processes. Their designs accommodate equipment like crushers, separators, graders, and more, ensuring they operate at optimal capacities.

- Safety and Compliance: Treatment processes can sometimes involve chemicals or generate waste. Little P.Eng. prioritizes safety and regulatory compliance, designing facilities that minimize environmental impact and risks to workers.

- Energy Efficiency: Many treatment processes are energy-intensive. Recognizing this, Little P.Eng. incorporates energy-saving solutions, from efficient machinery layouts to the use of alternative energy sources, thus driving down operational costs.

4. Bulk Material Transfer

Transferring bulk materials from one point to another, or even from one mode of transport to another, is a task that requires precision and speed.

- Transfer Point Design: Little P.Eng. is adept at creating transfer points that minimize material loss. Whether it’s transferring grain from a truck to a silo or coal from a railcar to a ship, their designs ensure smooth transitions.

- Material Integrity: When transferring materials, there’s a risk of contamination or degradation. Little P.Eng. addresses this by designing enclosed transfer systems or integrating rapid sealing mechanisms.

- Automation and Technology: In an age of technology, Little P.Eng. leverages advanced automation systems in their transfer point designs. This not only speeds up the transfer process but also reduces human errors.

Little P.Eng.’s Journey to Excellence

At its core, Little P.Eng. Engineering’s success can be attributed to its comprehensive approach. Instead of viewing these four sectors in isolation, they consider them parts of a holistic system. Their designs, thus, seamlessly integrate across the spectrum, from handling facilities to transfer points.

Client-Centric Approach

Little P.Eng. has always prioritized the unique requirements of its clients. They understand that every industry and even individual businesses within those industries can have varying needs. This client-centric approach has resulted in solutions that aren’t just efficient but are also tailored to the specific challenges and objectives of their clientele.

Embracing Future Challenges

As the world continues to evolve, so do the challenges associated with bulk material management. Little P.Eng. Engineering, with its commitment to research, innovation, and adaptability, is well-equipped to tackle these challenges head-on.

With a growing demand for efficiency, safety, and sustainability, industries will find in Little P.Eng. a partner that’s not just equipped to meet these demands but one that’s committed to exceeding expectations.

In the world of bulk material management, Little P.Eng. Engineering stands tall, not just as a solution provider but as an innovator and trailblazer. Through their expertise in structural and mechanical design across the four critical sectors detailed in this article, they’re not just shaping industries but also the very future of bulk material management.

Little P.Eng. Engineering’s Bulk Material Handling Team is a dynamic and diverse group with experience in conveying systems – mechanical and pneumatic; chutes transfers, dust control & collection, etc. Our experience in material handling for the power and manufacturing industries will provide rapid development of realistic concepts, and reliable designs which optimize operating and maintenance cost for your project. Our goal will be to not only deliver successful design to the field but to provide you with the information you need to make informed decisions to meet your objectives.

For industries such as mining, refining, manufacturing, chemical, agricultural, and food and beverage, this experience in material handling provides rapid development of realistic concepts, and reliable designs which optimize operating and maintenance costs for your project.

Industries served through our Bulk Material Handling Engineering Services

- Grains

- Mining

- Mills

- Metals

- Manufacturing

- Maintenance

- Fabrication

- Agriculture

- Packaging

- Safety

- Fire & Explosion

- Ship/Barge Loading & Unloading

- Steel and Metals Industry

- Energy and Power Generation Industry

- Water and Wastewater Industry

- Oil & Gas Industry

- Chemicals and Plastics Industry

- Pulp & Paper Industry

- Facility Services

- Residential Buildings Sector

- Hospitality and Hotel Sector

- Commercial Buildings Sectors

- Sports and Stadia Buildings Sector

- Education Buildings Sector

- Government Buildings Sector

- Hospitals Engineering Services

- Biotech / Pharmaceutical – Engineering Services

- Food & Beverage – Engineering Services

We offer the following Engineering Services within our Bulk Material Handling Engineering Services :

- Discrete Element Modeling (DEM)

- Calculation based modeling

- Allows for visualizing results

- Particle velocity

- Forces (shear and normal) and moments (bending and torsional)

- Acceleration and material scatter

- More than just flow simulation of bulk materials

- wear Patterns

- Mixing

- Center loading

- DEM Benefits

- Reduced Dust Levels

- Reduced Noise

- Reduced Chute Plugging

- Better Conveyor Tracking (Center Loading)

- Reduced Belt Cover Wear

- Reduced Chute Wear

- Reduced Equipment Wear

- Structural Engineering Services

- Foundation Design

- Concrete Structure Design

- Steel Structure Design

- Piping Engineering Services

Bulk material handling engineering specifically focuses on the design, processing, and transportation of bulk materials, which can include items such as ores, coal, minerals, and grains, among others. These materials often present unique challenges due to their bulk nature, including issues related to flowability, abrasiveness, corrosiveness, weight, and other specific characteristics. Here are the various aspects of bulk material handling engineering services:

- Storage Solutions:

- Design and layout of silos, bins, and stockpiles

- Assessment of material flow properties to reduce issues like bridging or rat-holing

- Conveyor Systems:

- Design and optimization of belt, screw, chain, and pneumatic conveyors

- Selection of appropriate conveyor belts, idlers, and drives

- Loading and Unloading Systems:

- Railcar and truck loading/unloading facilities

- Ship and barge loading/unloading equipment

- Reclaiming Systems:

- Design of stacker-reclaimers, bucket wheel reclaimers, and scraper reclaimers

- Size Reduction Equipment:

- Crushers, grinders, and milling equipment

- Sizers and chutes to manage particle sizes

- Screening and Sorting:

- Vibrating screens, trommels, and sorters

- Density separation using jigs or cyclones

- Feeding and Metering Equipment:

- Feeders for accurate and controlled material flow

- Rotary valves, weigh feeders, and volumetric feeders

- Material Transfer:

- Chutes, hoppers, and gates

- Transfer tower and junction house design

- Dust Control and Suppression:

- Dust collection and filtration systems

- Wet suppression and foam suppression systems

- Safety and Environmental Considerations:

- Explosion and fire protection in dusty environments

- Erosion control and spill prevention

- Flow Aids and Devices:

- Vibrators and air cannons to aid material flow

- Flow liners and internal coatings

- Bulk Material Testing:

- Evaluating flowability, abrasiveness, and other material properties

- Moisture content and material density testing

- Rail and Marine Infrastructure:

- Rail siding design and layout

- Port and harbor infrastructure for bulk material export/import

- Automation and Controls:

- Automated monitoring of material levels in bins and silos

- Control systems for conveyor speed, material flow, and routing

- Maintenance and Wear Protection:

- Wear liners and abrasion-resistant materials

- Maintenance strategies and schedules

- Bulk Material Transport:

- Pipeline transport for slurry and other bulk fluids

- Pneumatic transport systems for powders and granules

- Economic Analysis:

- Cost estimation for bulk material handling projects

- Return on investment (ROI) calculations

- Regulatory Compliance and Standards:

- Ensuring designs meet relevant industry standards

- Adherence to safety and environmental regulations

- Continuous Improvement and Upgrades:

- Evaluation of existing systems for performance enhancement

- Retrofitting and upgrading older infrastructure

- Consultation and Advisory Services:

- Providing expertise on specific bulk material challenges

- Assisting with vendor and equipment selection

Given the unique nature and challenges of handling bulk materials, these services are essential to ensure efficient, safe, and economical processing, transportation, and storage. Properly designed and managed systems reduce product loss, minimize environmental impacts, and ensure safety while optimizing costs.

Tags:

- Little P.Eng. Engineering

- Structural design

- Mechanical design

- Material handling

- Bulk material transport

- Treatment facilities

- Bulk material transfer

- Conveyor systems

- Infrastructure design

- Pneumatic transport

- Refining

- Material grading

- Compliance

- Transfer points

- Energy efficiency

- Dust suppression

- Material contamination

- Bulk material degradation

- Silo design

- Loading docks

- Client-centric approach

- Workflow optimization

- Advanced ventilation systems

- Single-boom spreaders

- Environmental impact

- Risk assessment

- Sustainable engineering

- Material integrity

- Client testimonials

- Automation in material handling

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.